Our Quality management

Directly to the info »

Post-annealing | X-ray examination | Vicat measurement

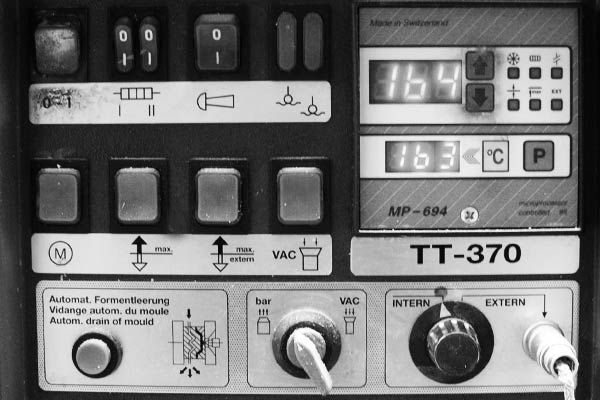

Post-annealing

Highest demands on dimensional accuracy

If particularly high demands are placed on dimensional stability, the workpiece is re-annealed for several hours before undergoing final machining. The crystalline structure can then re-align itself in the heated material. Any tensions that may have been caused by cooling or machining are eliminated and the finished part will meet even the most stringent requirements on dimensional stability. This „artificial ageing“ also enhances the properties such as toughness, rigidity, wear resistance, hardness.

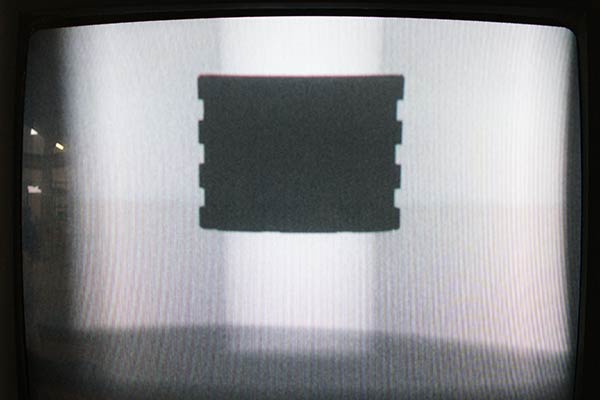

X-ray examination

We have the perspective

When producing HAWAMID PA 12G, strict requirements concerning the observance of procedures must be met; because even the slightest deviations from the production process will result in irregularities in the plastic structure and thus result in weak spots. In order to ensure maximum possible product safety, all HAWACAST parts potentially exposed to risks undergo x-ray examination prior to being delivered.

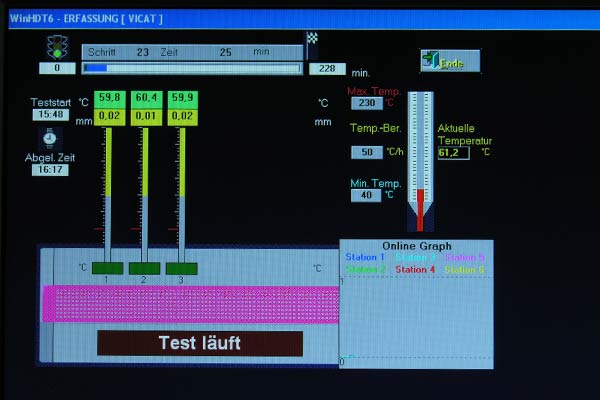

Vicat measurement

Permanent measurement creates quality and safety

With the help of Vicat measurements the production batches are constantly monitored. In the case of deviations in the parameters we can immediately intervene by making adjustments to the production process. The curve shape and the final temperature show the development of the material parameters hardness and toughness under controlled heating. This way, different materials and different production batches of a material can be compared.

Three materials in direct comparison: POM softens already at 60°C and then gradually becomes softer. PA 6 is the last to soften, but therefore deforms much earlier (see also elastic modulus). PA 12G remains solid and elastic up to 150°C.

Certification

Download Certification