Technischer Anhang im Überblick

Diagramme zu HAWAMID PA 12G

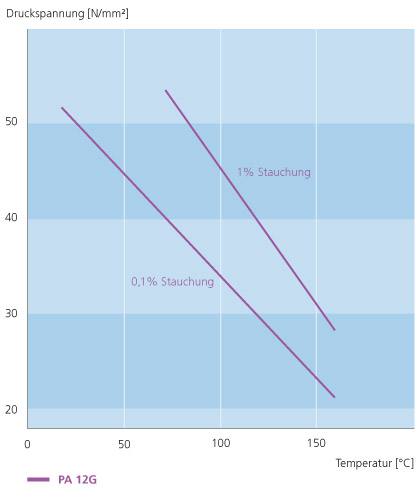

Druckspannung / Temperatur

Schon bei Raumtemperatur von 23°C liegt die zulässige Druckspannung von PA 12G um 43% bzw. 31% höher als bei POM oder PA 6. Steigt die Temperatur, sind die Einsatzgrenzen bei POM und PA 6 schnell erreicht. PA 12G hingegen zeigt über ein breites Temperaturintervall ein gutes Rückstellverhalten und geringes Kriechverhalten.

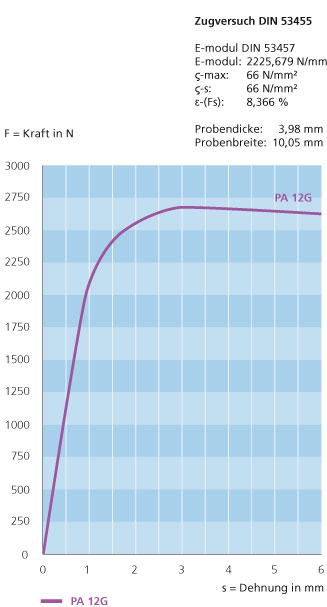

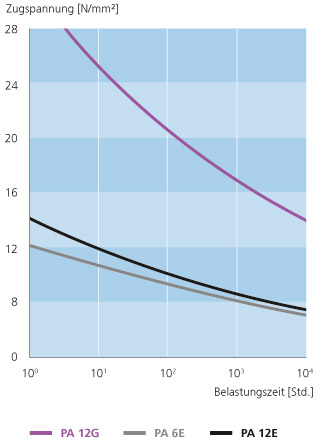

Zugspannung / Belastungszeit

Der direkte Vergleich von gegossenen zu extrudierten Polyamiden – d.h. der Vergleich von Polyamiden mit hoher zu niedriger Kristallinität: Das hochkristalline, gegossene PA 12G kann weitaus höher und länger belastet werden als die niederkristallinen, extrudierten Polyamide PA 12E und PA 6E.

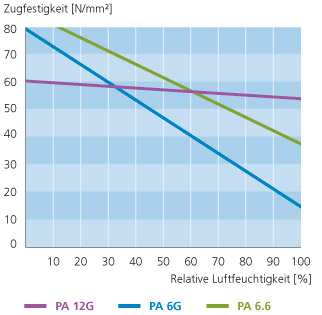

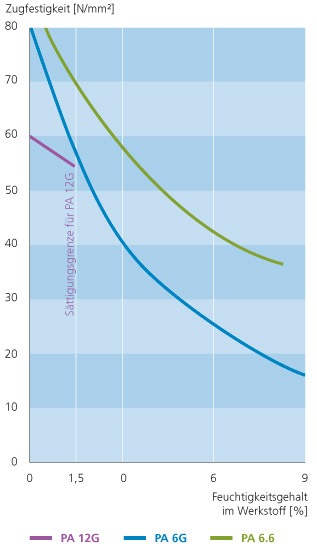

Feuchtigkeitsaufnahme / Relative Luftfeuchtigkeit

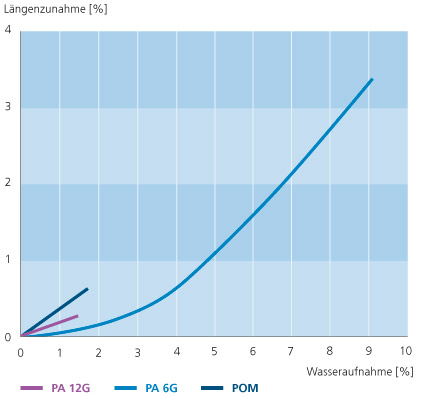

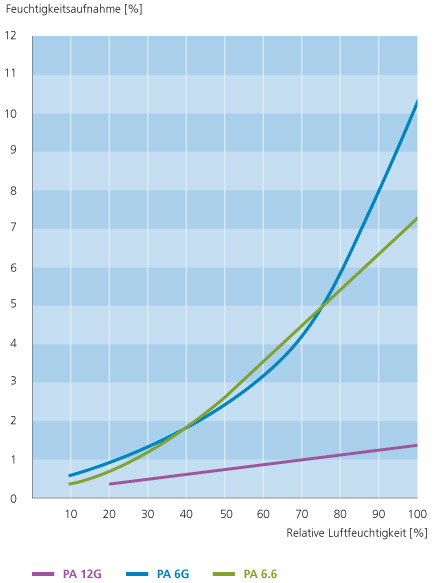

Die hohe Feuchtigkeitsaufnahme von PA 6 hat eine geringere Festigkeit und bedingt durch das Quellverhalten eine geringere Maßhaltigkeit zur Folge. Bei Frost besteht zudem die Gefahr des Berstens. PA 12G hat mit 1,1% seine Sättigung erreicht – das bedeutet eine konstante Maßhaltigkeit und Festigkeit auch in feuchter Umgebung und bei Temperaturen bis -50°C.